Leading industries through the digital transition

Digital is a part of everything and everyone in this day and age, right? More or less. The vast majority of companies and organizations are in the midst of a transition to become truly digital. Those who don’t digitalize fast enough will eventually fall too far behind to catch up. In the Northern Netherlands, this challenge is seen and tackled. Here the future is taking shape. In all sectors.

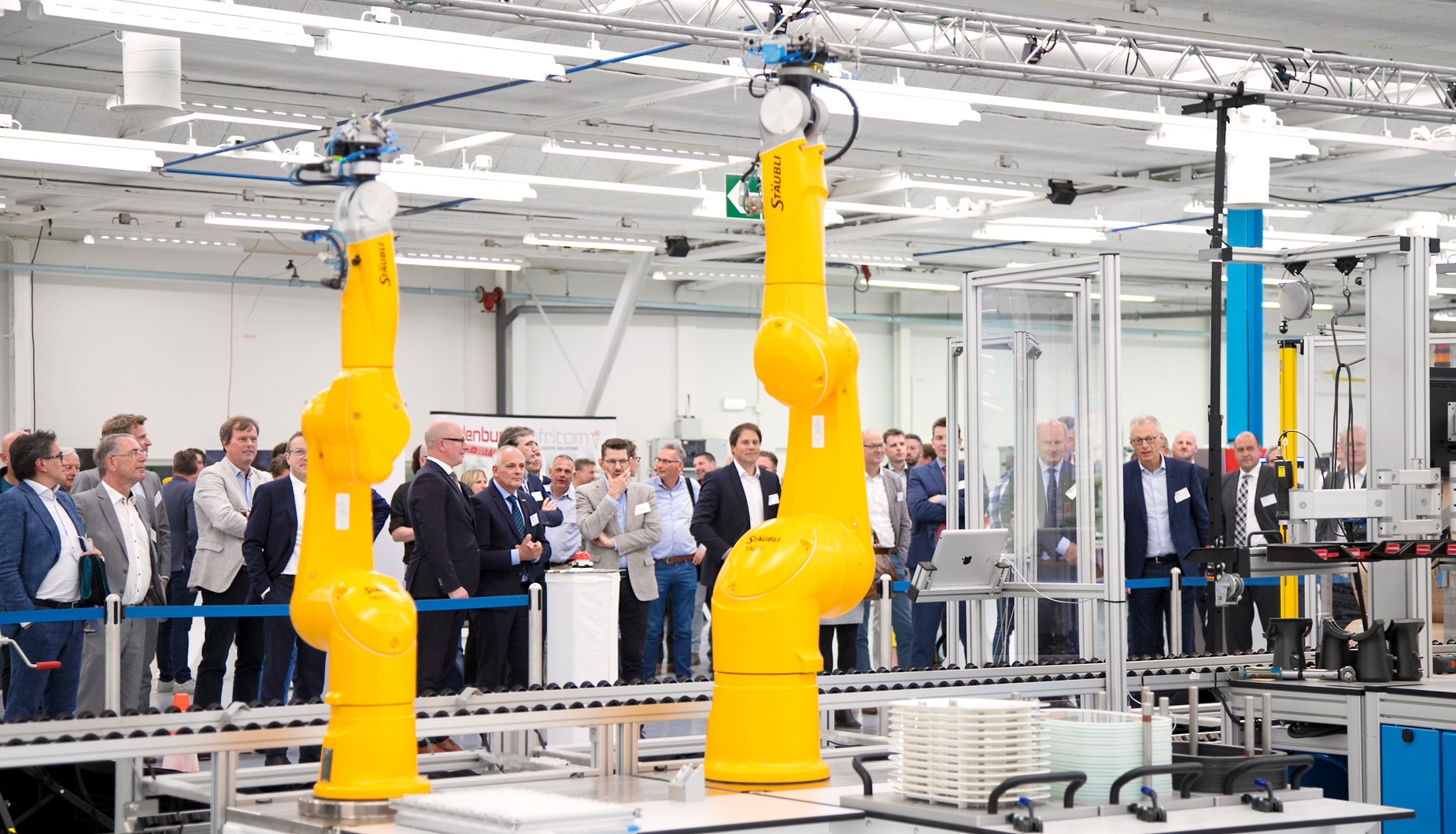

We’re in the Northern Netherlands. It’s spring 2022. In a factory, a robotic arm starts moving. It gets to work, fully automatically, with its chisel, drill and milling cutter. The drone flying through the warehouse notes that a specific product’s stock is low and needs to be topped up, so starts the production process. As a result of machine learning, the operating system, just a few seconds ago, concluded that demand for that product will increase in the coming weeks.

‘Digital’ goes further than automation.

Thanks to data being collected from all sides, combined with artificial intelligence and machine learning, the market is becoming more and more predictable. Webstores can see which items will soon be in high demand, a maintenance firm knows where streetlighting is about to fail, and a factory knows there will soon be a shortage of raw materials. Changes in the logistics process are, thanks to blockchain technology, immediately clear to all stakeholders and adjusted.

The digital transition applies, in short, to all sectors. Their newcomers know that. They are able to disrupt the market. The struggle has begun for existing companies. Knowledge is key. And one of the keyholders is the TopDutch region.

Unique combinations

Large, high-tech companies collaborating with scientific research groups, SME entrepreneurs who know how to make the most out of help from governments and schools: Cross-connections make up more than the sum of their parts. The TopDutch region is a part of a country where the lines are short, and awareness of the common interest is high. These are great ingredients for a dynamic approach to the digital transition.

Jan Post, professor of Digital Fabrication at the University of Groningen, explains: ‘The smart networks in our region make a lot of things possible. You can see that the digital transition is receiving attention in many sectors. Energy, healthcare, bioplastics, agriculture, recycling, new raw materials, waste processing… the list is pretty much endless. Fundamental science into digital technologies is being done at the University of Groningen, while practical applications are being researched at the universities of applied sciences in the region. And throughout the processes the work is done in collaboration with companies’.

One of the important companies in this research is Philips, a well-known environment for Post. For thirty years he was responsible for the development of new products on the roadmap to the ‘smart factory’. ‘At Philips in Drachten, many million shaver heads are produced every year, to micron-level precision,’ illustrates Post. ‘That is only possible with an advanced form of digital manufacturing’. The strategic cooperation between TopDutch companies and educational institutes that provide help to them is invaluable to Philips.

Jan Post is more or less a living example of this. He uses his experience at Philips to assist more companies in their digital transformation. And also lends scientific research from the univeristy to this. ‘The foundation in the Northern Netherlands is strong. We can do everything. Supply, research, implement. The expertise in artificial intelligence and machine learning is extraordinary and can be used across very different subjects. And we’re only at the beginning. The roadmap has been rolled out; our joint goals are becoming increasingly clear.’

Fundamental science into digital technologies is being done at the University of Groningen, while practical applications are being researched at the universities of applied sciences in the region.

Jan Post, professor of Digital Fabrication at the University of Groningen

Industry 4.0

If you want to know what the future of industry looks like, you should pay a visit to Technologies Added, in Emmen. This is the place where the newest technologies in Industry 4.0 are being put into practice. Products from all over the world are rolling off the conveyor belt. Professional cargo bikes, water filters, smart streetlighting, electric scooters. It can all be made there. And more.

‘We have the answer to the requests and expectations of the consumer of tomorrow, and today too,’ says their director, Rob Goossens. ‘Think about something like a scooter. The days where you, as a consumer, had to choose between a limited number of different packages has gone. Now you can choose your color, your engine type, other accessories; and your scooter will be made exactly how you want it. And you’ll get it quickly too.’

Radical rethinking

What Technologies Added can do, that conventional industry finds difficult, is make unique products. Thanks to super-smart collaboration between digital systems, alongside modular workstations designed in-house, the smart factory gives great benefits to the consumer. The production line in the factory can be adjusted in no time. Working with a large surplus of parts is unnecessary. The production process won’t start until a consumer has made an order. As a result, having to put unsold products on discount is a thing of the past. No more waste. Also, making only what you need from close to home, rather than shipping full containers from far away, makes local manufacturing cheaper.

Technologies Added is another example of the TopDutch cooperative mindset: A shared smart factory. The appeal? ‘Many producers do not have money in the bank to set up their own production line. Reasonable. Thanks to our system, it can be much cheaper and more efficient,’ explains Rob Goossens.

All of this becomes possible thanks to digital thinking, both from the factory itself and from the circle of logistics partners and suppliers around it. Joris Bisschop, Operations Manager at Technologies Added, often has to explain how it all works and how it’s possible. ‘This is new. We were the first in the world, but nowadays you can see some similar factories popping up. The digital technology is how we managed it. But what really matters is a radically different way of thinking. It’s no longer about man-hours, raw material costs or the margins per batch. It’s about producing efficiently, on demand.’

The digital technology is how we managed it. But what really matters is a radically different way of thinking.

Joris Bisschop, Operations Manager at Technologies Added

Digital heart

The sophisticated digital heart works as so: A 3D model of a new product is encoded, a product configurator gets set, data about the costs and running time are linked-up. Information about how to make the products is sent to the machines at the workstations and also to the touchscreens where the operator can see exactly what they have to do. The logistics service provider knows, via the digital platform, exactly which parts should be delivered to where, and when they are due. The supplier of said parts receives a digital signal that they must be produced. And finally, a unique, personalized product rolls off the belt and a digital twin is stored in the database. ‘The next step is to add sensors to the products, so that we can predict when maintenance is required. That will all be recorded in the digital twin, which acts as the the basis for implementing improvements to the actual product’ furthers Goossens.

5G field lab

More efficient, more accurate and faster. This describes the new standard for mobile data traffic: 5G. In Groningen, in the TopDutch region, this new technology is being extensively tested. 5G too could become an indispensable factor in the digital transition. In industry, but also in agriculture, healthcare, energy supply, traffic and logistics, education, as far as the imagination reaches.

‘Data exchange is being used more and more in industry. Just think about, for example, the growing number of sensors being used. With 5G technology we can optimally coordinate them,’ says 5Groningen Program Manager Peter Rake. ‘Large data traffic can be effortlessly shared between engineers and machines using 5G. And it doesn’t have the limitations that WiFi has in terms of volume or vulnerability to theft’.

Finding the future in Groningen

Potential applications for industry are the focus of the ‘5Groningen’ 5G field lab, which was founded by the Economic Board Groningen. In collaboration with research institutes and different market participants, they work to jump-start economic activity. Innovative entrepreneurs and organizations can apply to develop their 5G applications in the testing ground, whose scope is unique in Europe. With self-driving shuttle buses, smart ambulances and an abundance of drones, stepping into the rural field lab in North Groningen is like stumbling into a vision of the future.

In the 5G field lab, significant numbers of experiments are already taking place with the technology, which is not yet accessible in the outside world. For example, there’s one test with a drone that carries out an inspection of production facilities in a factory through cameras that transmit real-time images. A smart, miniscule screen that can be used for passing on information such as manuals and orders, but also shoots real-time images is another project. This can easily generate Virtual Reality and Augmented Reality training manuals for product engineers, who can watch from the other side of the world.

What is unique here is that businesses can come to the 5G lab to test their applications. They can test outside, in Groningen’s agricultural hinterland, or inside a commercial property.

Peter Rake, 5Groningen Program Manager

Speeding up digitalization from the ground to space

‘There’s a limit to the scale of digital transformation if you only use 4G and WiFi’ says Peter Rake. ‘With 5G the possibilities are much greater. We’re moving towards 100x the data speed. And at the same time, sensors can work with much less energy, meaning the batteries will last much longer. What is unique here is that businesses can come to the 5G lab to test their applications. They can test outside, in Groningen’s agricultural hinterland, or inside a commercial property.’

The manufacturing industry is just one of the sectors with which 5Groningen is working to speed up the digital transition. Important developments in the Life Sciences and Health sector are also taking place. Thanks to 5G, ambulance personnel have a high-quality, super-fast video connection with specialists in the hospital, which means they have the ability to offer more help to the patient en route.

A drone that accurately, and in real-time, maps out the activities within all the parameters of a farmer’s field is an example of a project that is accelerating the digital transition in agriculture. And a machine that measures water quality in a lake, regularly used in all sorts of industries, is made smaller, faster, cheaper and more precise thanks to 5G technology.

The sky’s the limit for 5Groningen. Literally. ‘We also work together with the European Space Agency (ESA),’ says Rake. ‘Linking our technology and knowledge, we can measure air quality from space. This is of great importance for companies that deal with indoor climate control. They use this data to adjust when, and how much, air they let into a building’.

Healthcare

Digitalization is also rapidly gaining importance in healthcare. There are great possibilities, for example, in performing diagnostics with the aid of machine learning. And the use of digital tools can simplify administration; we’re already seeing that a well-secured digital patient file can result in better and more efficient assistance.

Facilitating data science in health

In the University Medical Center Groningen (UMCG), the digital advantage is becoming more and more recognized. ‘We are not only working on the use of digital devices to treat patients better. We also put a big emphasis on prevention. We’re on the road to personalized health. Without digital devices that just wouldn’t work,’ says Michiel Hooiveld, staff advisor and liaison officer at the Data Science Center in Health (DASH), of the UMCG.

The main task of DASH is data science-based projects that benefits patients. Chief Scientific Information Officer and professor of Clinal Neuroengineering Natasha Maurits is closely involved with DASH. ‘The nice thing is that we also connect the whole region. Companies and educational institutions get involved and think together. We believe that when we work together, we can achieve the best results.’ DASH also joins forces with other hospitals in the region. ‘That’s the power of the TopDutch region, there’s no sense of competition here. Not between the individual hospitals, nor between hospitals and commercial parties. We like to work together and, through this, extraordinary things arise.’

A changing skill set

Digitalization is changing the way that hospitals work and different job roles are becoming available. There are already more data analysts working in hospitals, and other jobs for which a technical background is required too. Michiel Hooiveld explains: ‘In all the data we collect lies many answers and solutions. We want to get as much out of it as possible.’

That’s the power of the TopDutch region, there’s no sense of competition here. We like to work together and, through this, extraordinary things arise.

Natasha Maurits, Chief Scientific Information Officer at the Data Science Center in Health (DASH)

Digital solutions making patients healthier and practitioners happier

The UMCG works with Lifelines, for example, whose large-scale research collects huge amounts of data about the effects of genetics and lifestyle on health. ‘By analyzing the data, we are increasingly able to identify predictive factors for health risks’ Hooiveld carries on. Many companies in the TopDutch region are working on digital solution to chart these health risks, improve the lives of patients, and those of healthcare professionals as a result.

ZiuZ Visual Intelligence, from Gorredijk in the Province of Friesland, is one such company. They have developed a machine that greatly reduces the margin of error in the packaging of medicine. Before them, one in every 200 pills ended up in the wrong pack. Now, with the new machines, the margin of error is down to one in every 1.3 million. ZiuZ manages this with the use of highly sophisticated cameras, in combination with machine learning.

‘We are working on more projects, including projects with the UMCG,’ says their founder and owner, Gerrit Baarda. ‘This is how we are developing a method for recognizing particular movement disorders, that are often missed in diagnostics by humans. We’re now teaching our machines what factors they should pay attention to, based on lots of data and machine learning. Projects like this are possible here in the TopDutch region because healthcare professionals and entrepreneurs can find easily each other.’

CONTACT

Join TopDutch

So what will be your next move? How will your company lead the digital transformation? Contact our network of knowledge-intensive institutions and innovative and entrepreneurial companies. You’ll soon see for yourself how quickly things get done here in the Northern Netherlands.

TopDutch Digital Innovation Package

Get your hands on:

- Unlimited access toTopDutch Digital Innovation articles

- The most exclusive investment updates, industry insights and key stories from our key industries

- Invites to exclusive international industry events and meet-ups

"*" indicates required fields