5 disruptive trends for tomorrow’s logistical infrastructure

The Netherlands is the world’s most logistically connected country. With its central location between the three largest European economies, its long seacoast, its outstanding air transport links to the rest of the world, its important position in internet infrastructure, its highly educated workforce, and its open culture, the country is one of the most attractive business locations. In the north of the country, the TopDutch region, the infrastructure for the distribution of the future is already being created thanks to pioneering entrepreneurs. Here’s five disruptive trends developing in the TopDutch region that contributes to the Dutch title of the DHL’s Most Logistically Connected Country.

TopDutch: Forerunner in electric and hydrogen-based mobility

In 2017 the world’s first hydrogen-powered Tesla drove through the beautiful TopDutch landscape. It was named the Hesla, by its creator Max Holthausen. The story of this went viral worldwide – within moments countless people had heard about this new innovation. The vehicle wasn’t the brainchild of Elon Musk, but the Dutch family business Holthausen. The company optimized a Tesla by having a hydrogen fuel cell installed, which charged the battery. The result? The driving distance of the electric car tripled: the Hesla can drive 1,000km - instead of the 350km of an electric Tesla (621 miles instead of 271) - on one tank.

The Hesla gives us a glimpse into the future of mobility, and the possibilities in hydrogen. Over the next 10 years we’ll see a worldwide transition from fossil fuels to vehicles fueled by climate-neutral energy. Hydrogen offers a significant opportunity for powering long-distance or energy-intensive vehicles in a fully sustainable way. In order to achieve this opportunity, it involves a new infrastructure and applied knowledge – both of which are strong in the TopDutch region. Therefore, the TopDutch region is investing heavily in the hydrogen economy, which will revolutionize the world of logistics and transport in the coming years.

Ten years ago, we foresaw that the world would change. We began looking for new market opportunities for our company. That opportunity became hydrogen.

Stefan Holthausen

Holthausen itself is an example of this. For 75 years, the company has been active in the scaling and distribution of industrial gases, and it cooperates with chemical companies such as Nouryon, and other firms like Remeha, which supplies the built environment with heating systems, or energy-supply firms Enexis and Gasunie.

For example, the family-run business was a supplier to companies that built and maintained the natural gas network of the Netherlands and Western Europe. Stefan Holthausen, cousin of Hesla designer Max, and grandson of founder Carl Gerardus Holthausen – who sold filled gas canisters on his cargo bike after the war – is the current general manager of the company. In addition to supplying gases to industrial companies, Holthausen is a leading pioneer in the innovative application of hydrogen to the world of mobility.

‘Ten years ago, we foresaw that the world would change. So, we began looking for new market opportunities for our company’. That opportunity became hydrogen. The company has been supplying hydrogen since its foundation. But in the application of green hydrogen in particular, Holthausen saw a strong future.

Hydrogen as a missing link for the electrical future

Holthausen sees hydrogen as the missing link in the transformation from fossil fuels to sustainable energy sources. The generation of electricity from renewable sources such as wind and sunlight has expanded in recent years, but the storage of such energy has shortcomings. For example, the batteries are made of heavy metals, which are a major drain on natural resources, and they lose their storage capacity over time. The current infrastructure of the electric grid cannot meet the huge energy needs of electric cars. According to Holthausen, energy storage is the key to the future energy infrastructure. Hydrogen, although less energy efficient at the moment, will be the energy storage mode of choice in the future.

Through electrolysis, water can be converted into hydrogen, which can be converted back into electricity by combustion. Partly as a result of the amount of energy loss – 50 to 75% – that comes with this conversion, the cost of hydrogen is still currently relatively high, around €10 per kg. Holthausen expects that, if the technology develops and the production volume and energy efficiency increases, the price will fall. The tipping point that would make hydrogen as a fuel economically interesting would be a price of around €5-6 per kg, and €2-3 per kg for a disruption of the vehicle fuel market, estimates Holthausen. The latter would also have a revolutionary impact on the use of hydrogen as an industrial feedstock, as a storage medium for energy and as a source of heat for the built environment.

To stay ahead of the future, Holthausen is already building hydrogen-powered vehicles – mainly vans – with a fuel cell, but without a heavy electric battery. ‘This gives the vehicles a longer range, greater carrying capacity, and a lower charging time.’ This is what leads Holthausen to believe in a future of hydrogen technology for heavier vehicles that travel longer distances; such as vans, trucks, trains and ships. In the city of Groningen, in the TopDutch region, there are 164 electric buses, that cover a 150km (93 miles) range. In the extended-city zone, there are 22 hydrogen buses, which can cover longer distances with one tank.

Training the mechanics of the future in the TopDutch region

Although, currently, automobile manufacturers are only producing a few thousand hydrogen cars a year, the production levels increase significantly on a yearly basis. In the future market, specialized technicians will also be needed. In the TopDutch region, they are already being trained in universities of applied sciences and vocational colleges. To develop this, Holthausen works intensively with various educational institutions, such as NHL Stenden and Hanze Universities of Applied Sciences, the University of Groningen, and a number of vocational colleges. ‘The fuel cell technology profession is not fully developed yet, but we’re training the hydrogen engineers of the future by involving automotive engineering students in the production of hydrogen-powered vehicles. These students already know more than their teachers!'

Network of hydrogen fueling stations

Ultimately, however, a network of fueling stations will have to be built for hydrogen transport. In the TopDutch region, Holthausen built one 5 years ago. A solar farm with a generation capacity of 10MW is linked to an installation that stores the energy, via electrolysis, in hydrogen. This is how renewable hydrogen can be produced for us to fill our cars with.

Ten hydrogen stations are being built in the Netherlands: in addition to the first Energy Point Holthausen built in Groningen, there’s also locations at Schiphol Airport, Amsterdam, Utrecht, Arnhem, The Hague and, in the TopDutch region, in Pesse, near Hoogeveen. In the Northern Netherlands several pioneers are working on the infrastructure of the future. For example, Orange Gas – a company from Heerenveen – operates several hydrogen fueling stations, and are aided by Capital A (Previously ABN AMRO Participaties) as investors. Resato, from Assen, is involved in the construction of several hydrogen pumps. The company supplies complete hydrogen filling stations and test systems, including Resato's own high pressure compressors, with a working pressure of over 1,000 bar, which are indispensable for such filling stations.. As with Holthausen, the company also originated as a result of decades of expertise in natural gas from the TopDutch region. The high-pressure systems supplied by Resato are exported to 80 countries, particularly those where natural gas and oil extraction is developed. ‘The technology for hydrogen is very similar to that of natural gas’, says their CEO Rob Castien.

For the mobility of the future, hydrogen offers Resato greater opportunities than electric vehicles. Castien sees hydrogen as a clean alternative for today’s diesel engines. That’s why Resato is involved as a supplier in the construction of new hydrogen filling stations in the Netherlands. ‘The application of hydrogen technology is currently lacking behind that of battery-powered engines, but its development can’t be stopped.’ For instance, Castien states that refueling hydrogen takes considerably less time than it takes to charge a battery. ‘This makes hydrogen particularly suitable for long-distance transport and mobility.’

The Dutch Hydrogen Grid

Moreover, the Netherlands already has an extensive supply network. The well-developed natural gas pipes which has supplied the country with energy since the discovery of the Northern Netherlands’ natural gas reserves, after some small modifications, can be made suitable for the transportation of hydrogen. Already a first natural gas pipeline, between Sluiskil and Terneuzen, in the south of the Netherlands, has been converted in order to test large-scale hydrogen transportation. Castien believes that by 2030 the first long-distance pipelines in the TopDutch region will be usable for hydrogen.

The TopDutch region is located in a key area for hydrogen generation. This is due, in part, to the location on the German Bight of the North Sea; where, in addition to a number of Dutch wind farms, all of the German wind farms are located. Wind power generation requires storage capacity – something that can be achieved by converting it into hydrogen via electrolysis. The North Sea is already a significant source of energy, but in the future a constant supply of clean energy must come from the sea, which may be used in the form of hydrogen, predicts Castien. ‘The TopDutch region is the knowledge center of energy technology; here we know everything about transporting gases in large quantities.’

The Dutch king, Willem-Alexander, opened Hystock, the first hydrogen storage facility of the natural gas infrastructure organization Gasunie, in mid-2019. Hystock is a hydrogen plant where solar energy and green electricity from the Dutch electric grid are used to convert water into hydrogen and oxygen. Gasunie’s long-term goal is to store hydrogen underground in salt caverns in the TopDutch region, which reach a height as tall as the Eiffel Tower. In one cavern alone, 330 million cubic meters of hydrogen can be stored. This should be part of the North Sea Wind Power Hub – a central European hub for renewable energy and storage which will soon meet one fifth of Europe’s energy needs in the future.

Developing applications for 5G technology with the 5G Field Lab

The mobility of the future will need a second grid – the digital grid. In the TopDutch region, the Dutch government is innovating together with telecoms companies for the development of 5G technology. The fifth-generation mobile network can wirelessly exchange information faster, but also with less interference. With 5G, the large-scale exchange of data flows becomes possible for autonomous vehicles, amongst many other applications. In the TopDutch region a 5G field lab has been established to finance pilot projects for the application of this new technology.

One of these initiatives is the use of sensor technology to collect information on the status and location of hydrogen gas cylinders. Through the real-time collection of data, the supply of hydrogen fueling stations is optimized. There are also projects going on in the sphere of ship navigation near ports, for autonomous inland navigation on rivers and canals, for monitoring silt accumulation in the waterways, and for remote dredging.

Via the 5G Lab, the Netherlands is also pioneering the use of: buses that can be given priority at traffic junctions through communication via the 5G network; trucks that can benefit from a longer green traffic light through data exchange; and are adjusting the speed limit on provincial roads based on the volume of intersecting traffic. Already now, a self-driving bus is operating in the TopDutch region, which is used to investigate whether public transport for vulnerable groups can be maintained in sparsely populated areas.

Blockchain technology building the digital logistics infrastructure

The distribution logistics of the future also requires an administrative infrastructure, a digital standard for the transmission of information. This infrastructure is also being developed in the TopDutch region. Vinturas – initiated by the international logistics service provider Koopman Logistics Group – deals with this. Jon Kuiper, founder and CEO of Vinturas, developed blockchain-based technology for the digitalized waybills that transport companies use.

The story began in 2018 with a proof of concept that Kuiper designed together with IBM’s blockchain development center in Groningen. Vinturas now offers its logistic blockchain services all over Europe, and has shareholders in the Netherlands, Sweden, the Baltic states, France and Spain. Vinturas has built a strong position as an international digital service provider in the logistics chain for car manufacturers. ‘The digitalization of waybills enables transporters to provide real-time tracking and tracing of goods. This allows car dealers to inform their customers with details, such as that the new car is now on the quay, and which ship or truck it will be delivered in.’

The proximity of IBM’s Global Competence Center in Blockchain is crucial for us. Moreover, the University of Groningen has the largest supply chain faculty in Europe, including a living lab.

Jon Kuiper, founder and CEO of Vinturas

The details of the goods are scanned and stored on the blockchain as a digital delivery document, an electronic waybill. This not only saves on paper costs; it also prevents fraud with freight data. ‘Because it’s stored via blockchain, the freight document is immutable. This counteracts fraud, reduces insurance costs and can prevent unnecessary costs due to incorrect administration or fines.’ The document can also be used to collect additional data about shipments. In the importing and exportating of used cars, for example, it prevents the manipulation of odometer readings. ‘Fraud can be prevented by identifying a physical location and linking that geo-data to the person from the transporting company.’

The technology can be applied to other flows of goods. That’s what Vinturas wants to develop, from the TopDutch region. The choice for locating in the region is the logistic expertise that the Northern Netherlands has. The proximity of IBM’s Global Competence Center in Blockchain is crucial for us. Moreover, the University of Groningen has the largest supply-chain faculty in Europe, including a living lab.’ Blockchain evangelist and ideologue Rutger van Zuidam, Faculty Member at the Singularity University, organizes the annual Odyssey Hackathon in Groningen, attracting many blockchain pioneers to the TopDutch region every year. ‘Together they form a hypermodern digital ecosystem for supply-chain management in the region. And here we like to work together intensively. This attracts more and more ICT professionals to the TopDutch region,’ Kuiper concludes.

European Hyperloop Test Center locates in TopDutch

The future of mid-distance transport will not be dominated by aviation. At least, not if it’s up to Elon Musk and his Hyperloop. Climate-friendly high-speed travel (over 700kph or 435mph) should be possible in the near future. This technology will also be tested in the TopDutch region, where the European Hyperloop Center will be opened in 2022. This test center will have a 3km long track, in which vehicles can be moved by an electromagnetic propulsion system.

This mode of transport is CO2-neutral and very fast, says Hardt Hyperloop, the Delft-based company that operates the test center. It also offers opportunities for faster transport over shorter distances. For example, a trip between Amsterdam and Groningen should be only 15 minutes, the distance between the Port of Rotterdam and the TopDutch region would be 19 minutes and between Groningen and Hamburg would be 21 minutes. The test center will be open for organizations that want to test with the hyperloop – initially with the transportation of parcels. Cooperation between them should speed up the development of the high-speed train.

TopDutch develops business models for the circular logistics of the future

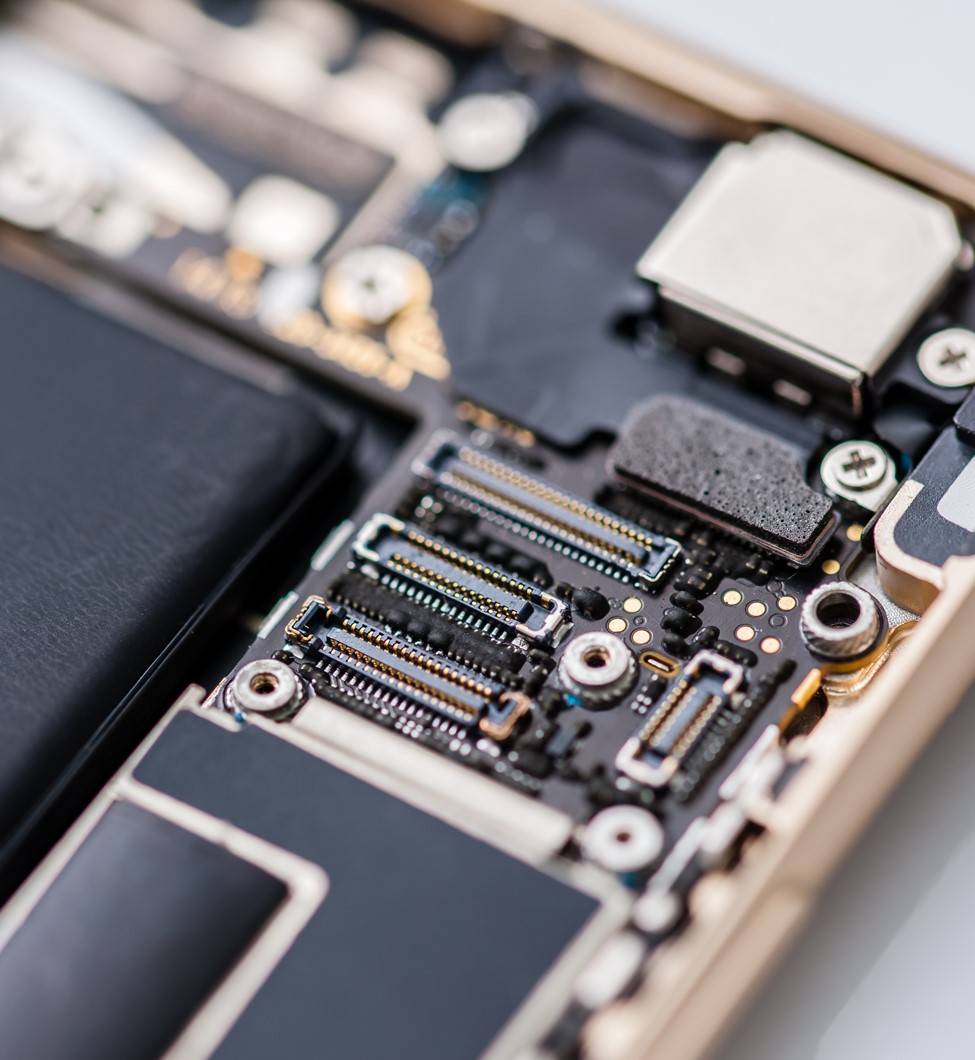

On the European continent, which is not rich in raw materials, there is a great need for new earning models for circular companies. Dr. Matthias Olthaar, a professor at NHL Stenden University of Applied Sciences, conducts practice-based research into the optimization of goods flow with more than 100 companies, mainly coming from the TopDutch region. After all, sustainable logistics also means minimizing waste and maximizing value creation; and the production of new goods by, for example, re-using raw materials – the so-called urban mining – is only economically interesting if the revenue model changes. Olthaar gives an example: ‘Take smartphones. Some of their parts are made in the TopDutch region. The raw material cost of a smartphone is about €5- while the selling price is one hundred times that. If you would recycle the device after depreciation and reclaim raw materials from it, the added value would be very limited. However, if you, as a manufacturer, could refurbish the product after depreciation, you could market your device a second time, including a margin.’

The region has an excellent business climate for circular businesses. The work ethic is high, the educational background of the local workforce is suitable for refurbishing products.

Dr. Matthias Olthaar, professor at NHL Stenden University of Applied Sciences

This presents challenges for manufacturing companies, Olthaar explains. ‘At the moment 9% of the Dutch economy is circular. The Dutch government is aiming for 50% by 2030 and 100% by 2050. That’s why Olthaar, together with a variety of firms, conducts research in how to lead the way. Several manufacturing companies from the TopDutch region are already circular and have a view on their complete supply chain. That’s necessary, says Olthaar: ‘In order to be able to refurbish, you need permanent access to your own products. There has to be a closed-loop supply chain and that’s challenging to realize. A common solution to this is that the producer remains the owner of the product, and the user leases the product. Thus the product must become a service. However there are alternative methods that can achieve the same thing, but are less complex to implement’.

For the producer, this requires virtual stock management of all products. Olthaar continues, ‘That’s where it often goes wrong. After all, where is all that virtual stock? And what’s the condition of each of the products after years of use? And when and how do they return?’ A closed-loop supply chain requires companies to be as flexible as possible. And the manufacturing industry needs logistic service providers that can support them in all these logistics processes. ‘There are enormous opportunities available for distribution logistics enterprises,’ claims Olthaar. ‘They can manage and absorb fluctuations in quantity and quality in return flows, and thus monitor where all products are.’ It’s one of Olthaar’s missions to solve this puzzle. He sees the TopDutch region as the hotspot for this challenge. ‘The region has an excellent business climate for circular businesses. The work ethic is high, the educational background of the local workforce is suitable for refurbishing products.’ And with the consumer market of Europe, there’s great access to the returns market of the future, he stresses. ‘Whereas an iPhone is made with materials from around the world, and assembled in China, it is likely to be refurbished for a second life in Europe. In the TopDutch region.’

Join TopDutch

So what will be your next move? What role will your company play in developing the next operating system for logistics? Contact our network of knowledge-intensive institutions and innovative and entrepreneurial companies. You’ll soon see for yourself how quickly things get done here in the Northern Netherlands.

Personal investment package

"*" indicates required fields